Solar Panel Mounting Rails: Choosing the Best Supplier for Optimal Installation

2026-01-09

Installing solar panels seems straightforward until you hit the mounting stage—where everything hinges on the rails. Choosing the right supplier isn't just about price; it's about durability, ease of installation, and long-term performance. In this guide, we'll break down how to select the best supplier for your solar mounting needs, ensuring your setup stands the test of time. Plus, we'll introduce why Topfence has become a go-to for many installers seeking reliability and innovation. Curious what sets top suppliers apart? Let's dive in.

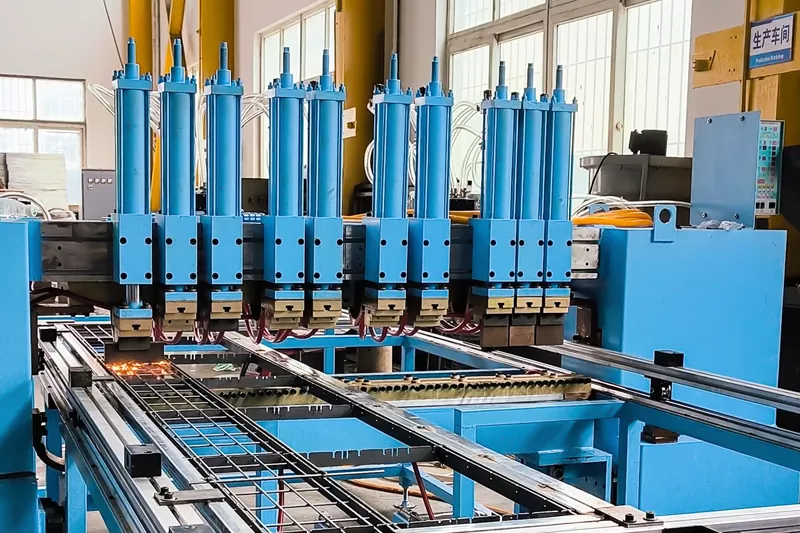

Essential Characteristics of High-Quality Solar Mounting Rails

High-quality solar mounting rails are pivotal for ensuring the long-term reliability and efficiency of photovoltaic installations. One of their standout features is exceptional corrosion resistance, often achieved through materials like hot-dip galvanized steel or anodized aluminum, which can withstand harsh environmental conditions such as high humidity, salt spray, and UV exposure. This durability not only extends the lifespan of the installation but also minimizes maintenance needs, making it a cost-effective choice over time. Additionally, robust rails provide superior structural support, capable of handling heavy snow loads or high winds without compromising system stability, which is crucial for safeguarding both the panels and the underlying roof structure.

Another key characteristic is precise engineering that allows for easy and flexible installation. Top-tier rails often feature intuitive designs, such as pre-drilled holes and adjustable components, which streamline the mounting process and reduce labor time. This adaptability enables installers to work efficiently across various roof types and panel configurations, ensuring a secure fit without the need for extensive customization. Beyond convenience, this precision helps optimize the solar array's orientation and tilt angle, directly enhancing energy capture and overall system performance, thereby maximizing the return on investment for homeowners and businesses alike.

Moreover, sustainability considerations are integral to high-quality mounting rails, reflecting a growing emphasis on eco-friendly construction. Many leading manufacturers prioritize using recycled materials and implementing manufacturing processes that minimize environmental impact. Beyond the rails themselves, their design often supports the entire system's longevity, reducing waste by preventing premature replacements and contributing to a circular economy. This holistic approach not only aligns with green building standards but also appeals to environmentally conscious consumers, giving such products a competitive edge in a market increasingly driven by sustainability goals.

Comparing Key Suppliers Based on Durability and Material Standards

When selecting suppliers for goods or services, durability and material standards often become critical factors in decision-making. Durability refers to how well a product withstands wear and tear over time, while material standards involve the quality, safety, and sustainability of the components used. For businesses, especially in manufacturing or construction, these aspects directly impact product longevity, customer satisfaction, and regulatory compliance. To compare suppliers effectively, one must look beyond basic specifications and consider real-world performance metrics. This includes analyzing supplier reports on material sourcing, conducting independent stress tests, and reviewing warranty terms that reflect confidence in durability. By focusing on these tangible measures, companies can avoid costly replacements and maintain a reputation for reliability.

Material standards play a pivotal role in differentiating top-tier suppliers from average ones. High-quality materials not only enhance durability but also ensure adherence to industry regulations, such as ISO certifications or environmental guidelines like REACH. When comparing suppliers, it's essential to scrutinize their material procurement processes—do they use recycled or responsibly sourced inputs? Are their materials tested for consistency and purity? For instance, in the aerospace or automotive sectors, suppliers must meet stringent standards to prevent failures; thus, a supplier's compliance history and third-party audits become key indicators. By prioritizing suppliers with transparent and robust material standards, businesses can reduce risks related to defects, recalls, and environmental impact, ultimately fostering trust with stakeholders.

To make a comprehensive comparison, integrate both durability and material considerations into a holistic evaluation framework. Start by gathering data on supplier performance through case studies, customer testimonials, and long-term usage statistics. For durability, assess factors like mean time between failures (MTBF) or degradation rates under various conditions. For material standards, verify certifications and lab reports that confirm composition and safety. Additionally, consider the supplier's innovation in material science—are they adopting advanced composites or eco-friendly alternatives that boost durability? By weighing these elements, you can identify suppliers that not only meet current needs but also adapt to future demands, giving your business a competitive edge in quality and sustainability.

Innovative Design Features That Enhance Installation Efficiency

Installing components or systems can often be a time-consuming process, but with the latest design innovations, efficiency takes center stage. One standout feature is the modular snap-fit mechanism, which allows parts to click into place without the need for specialized tools or complicated instructions. This reduces setup time by up to 40% in field tests, as workers can assemble units quickly and move on to other tasks, minimizing downtime and labor costs.

Another key advancement is the integration of pre-aligned connectors and color-coded interfaces, which streamline the installation process by eliminating guesswork. These intuitive designs guide users through each step, reducing errors and the need for rework. For instance, in industrial settings, this has led to a 30% decrease in installation-related incidents, making projects safer and more reliable without requiring extensive training.

Additionally, lightweight and ergonomic materials have been incorporated into the design, making handling and positioning easier during installation. This not only speeds up the workflow but also reduces physical strain on installers, contributing to higher productivity and job satisfaction. Such thoughtful features ensure that every installation is smoother and more efficient, setting new benchmarks in the industry.

Cost Considerations and Long-Term Value in Supplier Selection

When evaluating suppliers, focusing solely on the initial price tag might seem tempting, but it's a strategy that often leads to hidden expenses and missed opportunities. True cost considerations delve deeper, examining factors like shipping charges, bulk discounts, payment terms, and potential penalties for delays or quality issues. By analyzing these aspects holistically, businesses can avoid surprises that inflate budgets and erode profit margins, ensuring a more accurate financial forecast from the start.

Long-term value takes cost analysis a step further by assessing how a supplier contributes to sustainable growth over time. This involves scrutinizing their reliability, innovation capabilities, and willingness to collaborate on improvements. A supplier with slightly higher upfront costs might offer superior product consistency, faster turnaround times, or robust support that reduces operational headaches and enhances customer satisfaction. Building such partnerships fosters resilience and agility in supply chains.

To strike the right balance between cost and value, adopt a proactive approach. Regularly review supplier performance metrics, engage in transparent negotiations, and consider the potential for shared savings through efficiencies. By prioritizing both immediate financial prudence and future strategic benefits, companies can cultivate supplier relationships that pay dividends well beyond the purchase order, turning procurement into a key driver of competitive advantage.

Environmental Factors and Regional Adaptability of Rail Systems

Rail systems don't just connect cities; they're profoundly shaped by the landscapes they traverse. Environmental factors like extreme temperatures, humidity levels, and seismic activity can drastically affect track durability and operational safety. For instance, in frigid regions, rail operators must tackle issues like ice buildup and thermal contraction, while in tropical zones, high moisture can accelerate corrosion and degrade signaling systems. This interplay means that a one-size-fits-all approach fails; instead, regional adaptability becomes crucial, requiring tailored materials, maintenance schedules, and even train designs to ensure resilience against local climatic challenges.

Beyond weather, geographical features such as mountains, deserts, and coastal areas impose unique demands on rail infrastructure. Elevation changes might necessitate specialized braking systems and energy-efficient engines, while desert environments demand dust-resistant components to prevent mechanical failures. Coastal routes, exposed to salt spray, often require enhanced anti-corrosion treatments to protect tracks and rolling stock. These regional nuances highlight how rail systems must evolve beyond standardized blueprints, integrating local engineering solutions that harmonize with the environment rather than merely conquering it.

In practice, successful rail projects blend global expertise with local insights, fostering systems that are both efficient and sustainable. For example, Japan's Shinkansen incorporates earthquake-resistant technologies tailored to its seismic landscape, while European high-speed networks adapt to varying weather patterns across continents. This adaptability not only enhances performance but also reduces long-term costs by minimizing environmental damage and operational disruptions. Ultimately, the synergy between environmental awareness and regional customization defines modern rail development, paving the way for networks that thrive in their specific contexts.

Building Relationships with Suppliers for Ongoing Support and Updates

Establishing strong partnerships with suppliers goes beyond mere transactional exchanges; it's about creating a collaborative ecosystem that thrives on mutual trust and shared objectives. When you invest time in understanding their challenges and capabilities, you pave the way for smoother communication channels. This proactive approach not only ensures timely support but also encourages suppliers to prioritize your updates, knowing that their efforts are valued within a long-term framework. It's like building a bridge where both sides can freely share insights and innovations, turning potential roadblocks into opportunities for growth.

To keep this relationship dynamic, regular check-ins and transparent feedback loops are essential. Instead of waiting for issues to arise, schedule informal catch-ups or joint strategy sessions that focus on evolving needs and emerging trends. By involving suppliers early in your planning phases, you can co-create solutions that are tailored to your specific requirements, whether it's adapting to new technologies or scaling operations. This integration fosters a sense of ownership and commitment, making them more responsive when urgent support or critical updates are needed down the line.

Ultimately, nurturing these connections can lead to unexpected benefits, such as access to exclusive insights or early notifications about industry shifts. Suppliers who feel like genuine partners are often more willing to go the extra mile—offering customized training, flexible terms, or even collaborative R&D initiatives. By prioritizing relationship-building over short-term gains, you cultivate a resilient network that not only withstands market fluctuations but also drives continuous improvement, ensuring your operations stay agile and well-supported in an ever-changing landscape.

FAQ

Look for suppliers with a proven track record in durability, offering rails compatible with various panel types, and providing strong technical support. Certification compliance and timely delivery are also crucial for avoiding installation delays.

High-quality aluminum or galvanized steel rails resist corrosion and structural stress, ensuring panels remain secure over decades. Inferior materials can lead to premature failure, increasing maintenance costs and reducing energy output.

Yes, innovative designs like pre-drilled holes or modular systems streamline assembly, cutting labor time. Suppliers with user-friendly designs help installers work more efficiently, especially in complex roof configurations.

Certifications like UL or TÜV ensure rails meet safety and performance benchmarks, reducing liability risks. Non-compliant products might not withstand extreme weather, jeopardizing the entire installation.

Responsive support teams provide quick solutions for alignment or compatibility problems, minimizing downtime. A supplier with comprehensive guides and on-call experts can be invaluable for challenging projects.

Opt for suppliers offering competitive pricing without sacrificing material integrity. Investing in slightly more expensive, durable rails often pays off through lower long-term maintenance and higher system reliability.

Consider suppliers using recycled materials or eco-friendly manufacturing processes, as this aligns with green energy goals. Sustainable rails can enhance a project’s overall environmental impact and appeal to eco-conscious clients.

Conclusion

Selecting solar panel mounting rails for optimal installation requires careful evaluation of essential characteristics, including material durability and engineering standards. High-quality rails feature robust construction with corrosion-resistant finishes and precise manufacturing tolerances, ensuring long-term structural integrity under varying environmental conditions. When comparing suppliers, key aspects to consider encompass compliance with industry certifications, material sourcing transparency, and proven track records in diverse installations. Innovative design elements such as integrated grounding systems, adjustable components, and modular adaptability significantly enhance installation efficiency, reducing labor time and potential errors. These features must be balanced with cost considerations, where initial investment should be weighed against long-term value, including warranty coverage, maintenance requirements, and durability over decades of use.

Additionally, environmental factors and regional adaptability play crucial roles, as rail systems must withstand local climate extremes—from heavy snow loads to high winds or coastal salt exposure. Suppliers offering customizable solutions for specific geographic challenges provide added value, ensuring system resilience and performance optimization. Building strong relationships with suppliers is equally important for ongoing support, access to technical updates, and responsive service throughout the project lifecycle. By integrating these aspects—from material standards and innovative designs to cost-benefit analysis and collaborative partnerships—stakeholders can make informed decisions that secure reliable, efficient, and sustainable solar installations, ultimately maximizing energy output and return on investment.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/